.webp)

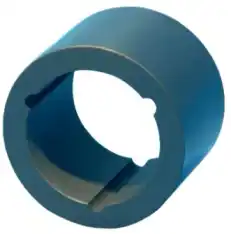

Tungsten carbide mechanical seal G92 seats

Seal Ring is a part of Seal. It is combinational part in,Rotary Stationary It is called as Rotary Ring and Stationary Ring. As a mechanical seal manufacturer we have much stock of seal rings. The different materials used in rings are Carbon seal rings, Silicon carbide seal rings, Ceramic seal rings, Tungsten carbide seal rings, satellite seal rings etc.

Minimum Order Quantity: 1 PIECE

Usage/Application: Seal part

Shape: Round

Heat : Proof Yes

Size: All Sizes

Application Mechanical Seal working condition: Water, oil, acids, alkali with low corrosion etc Size: 10~100 Key Words: G92 Stationary Seat Model: G92 Seat Style: Wave Spring Mechanical Seal Elastomer: NBR, EPDM, VIT, Aflas, FEP, FFKM

Silicon carbide Ring Mechanical Seal for water pump

Materials:Silicon Carbide

Stationary Ring: SIC,TC

Secondary Seal: NBR,EPDM,Vit

Silicon carbide Ring Mechanical Seal for water pump

Hardness : <2200HV0.5

Indicated

Parosity : <0.2%

Volume Density :

<3.00g/cm³

Compressive Strength : <2000Mpa

Fractural Strength :

<350Mpa

Coefficient Of Heat Expansion : 4 10 -6 1/<

Content of SIC

: <98%

Content of Free Silicon : <12%

Elastic Modulus : <350Gpa

Using Temperature : <1000<

(1) high hardness and wear resistance

(2) good corrosion resistance

(3) excellent mechanical strength

(4) good anti-oxidation

(5) good thermal shock resistance

(6) Low thermal expansion coefficient

(7) High thermal conductivity

Silicon Carbide Seal of G9 / G92 Stationary Seat Silicon Carbide SIC Carbon Ring

Product Description

G9/G92 (metric size) :

Materials : Stationary Ring:

Ceramic,SIC,TC,Carbon

Secondary Seal : NBR,EPDM,Vit

O ring mounted seats, with anti-rotation slot.According to

DIN24960/EN12756 standard.

Equivalent with Burgmann G9/G92 seal

Mechanical Seal Spare Parts Wg Stationary Seat Seal Ring

Our product including:

1: mechanical seals for water pump: equivalent with John Crane,

Aesseal, Flygt,GLF, and US Seal, etc

2: mechanical seals spare parts: made to order Silicon Carbide,

sintered silicon carbide seal rings, graphite carbon seal rings ,

tungsten carbide seal rings, O rings, springs, CNC machining service

mechanical seal spare parts WG stationary seat seal ring with 99.5%

ceramic, with anti-rotation slot.According to DIN24960/EN12756 standard.

Equivalent with John Crane WG seat.

Materials:

Stationary Ring : Ceramic,SIC,TC

Secondary Seal : NBR,EPDM,vit,PTFE

Silicon Carbide Seal 10t/10r Ptfe Ring

John Crane Mechanical Seal V Stationary Seat

Silicon Carbide Seal 10t/10r Ptfe Ring John Crane Mechanical Seal V Stationary Seat :

As An Industry Standard Design With A T-shaped Seat. With Two Ptfe Gasket Should Be

Clamped Structure.

Equivalent With John Crane V Stationary Seat

Materials :

Stationary Ring : Ceramic,sic,tc

Secondary Seal : Ptfe

G13 Stationary Seat Mechanical Seal Part

O ring mounted seats, with anti-rotation slot.According to DIN24960/EN12756 standard.Equivalent with G13 seat

Material : Silicon Carbide

Size : Standard

Application : Mechanical Seal Part

Key words : Stationary Seat

Stationary Ring : Ceramic,SIC,TC

Rotary Ring : Carbon/Sic/TC

Secondary Seal : NBR/EPDM/Vito

Equivalent : G13 seal

Feature : anti-rotation slot.

Parameter

Purity( % )

Hardness( HRA )

Grain Size( um )

Density( g/cm3 )

Bend Strength( MPa )

Compressive Strength(MPa)

Fracture Toughness( MPA )

Elastic Modulus( Gpa)

Thermal Conductivity(W/M.K)

Coefficient of heat Expansion( L/°C)

Poisson Ratio

SSiC

>98

92

0.5~0.7

3.10~3.15

400-580

>2200

3.05-4.6

>400

100~120

4.02x10-6

0.14

Silicon carbide G9 mechanical seal stationary seal

Our product range including mechanical seals equivalent with John Crane, Aesseal,

Flygt,Grundf, and US Seal,etc, Silicon Carbide Products,O-ring,Wave Springs.

Stationary Ring : SIC,TC

Rotary Ring : NBR,EPDM,FKM

The direction of rolling: looking from the stationary face,if the pivot be

rolled in clockwise direction,spring should be in right direction rolling

Chemical industry

Pulp and paper industry

Water and waste water technology

Sugar industry

Low solids content media

Cooling water pump

Basic sterile application

G9 stationary seat application range :

Pressure in the seal chamber: 0-1.2MPa

Temperature in the seal chamber: -30ºC--180ºC

Linear Velocity: < 10m/s

Medium: water,oil and minor corrosive liquid

Sinter silicon carbide SSIC seal mechanical seal rings

Product Description

Our product including:

1: mechanical seals for water pump: equivalent with John Crane, Aesseal, Flygt,GLF, and US Seal, etc.

mechanical seals model:

MG1/MG12/MG13/560A/560D/155/TYPE2100/TYPE8-1/TYPE9/M7N/H7N/M3N/

58U/58B/1527/GLF/912/FBD/301/F water seal/PTFE SEAL WB2 & WB3 etc.

2: mechanical seals spare parts: made to order Silicon Carbide seal rings, sintered silicon carbide

seal rings, graphite carbon seal rings ,tungsten carbide seal rings, ceramic rings, rubber O rings,

springs, CNC machining service.

application

it is usually be used in pumps , mechanical seal

Reaction Bonded Silicon Carbide (RB SiC) - a very economical material which gives excellent wear

characteristics, as well as good chemical resistance.

Sintered Silicon Carbide (SSiC) - the absence of free silicon makes it most resistant to chemicallyaggressive fluids, and ideal for high temperature applications.

Graphite-Loaded Silicon Carbide - this is a composite of silicon carbide and free graphite.

Graphite is added to RB SiC (RB SiC + C) or SSiC (SSiC + C), to improve tribological behavior by enhanced lubricity

Silicon Carbide Seal Sinter At Atmosphere (normal) Pressure Ssic Seal Ring

Silicon carbide have the property of excellent resistant-corrosion, high mechanical strength, high thermal

conductivity,good self-lubrication, used as seal faces, bearings and tubes in spacecraft, machinery, metallurgy,

printing and dyeing, foodstuff, pharmaceutical, auto industry and so on. When the sic faces are combined with

graphitefaces the friction is the smallest and they can be made into mechanical seals which are able to

work in highest working requirements.

Reaction Bonded Silicon Carbide (RB SiC) - a very economical material which gives excellent wear

characteristics, as well as good chemical resistance.

Sintered Silicon Carbide (SSiC) - the absence of free silicon makes it most resistant to chemicallyaggressive fluids, and ideal for high temperature applications.

1. Mechanical Seal

2. Heat Exchanger

3. Armour Plate

4. Ball Vlave Parts

5. Pump Components

6. Semiconductor

7. Metallurgical Engineering

8. Fixed and Moving Turbine Components

silicon carbide mechanical seal face with groove

1: Mechanical Seals For Water Pump: Equivalent With John Crane, Aesseal, Flygt,glf, And Us Seal, Etc.

Mechanical Seals Model :

Mg1/mg12/mg13/560a/560d/155/type2100/type8-1/type9/m7n/h7n/m3n/

2: Mechanical Seals Spare Parts: Made To Order Silicon Carbide Seal Rings, Sintered Silicon

Carbide Seal Rings, Graphite Carbon Seal Rings ,tungsten Carbide Seal Rings, Ceramic Rings,

Rubber O Rings, Springs, Cnc Machining Service.

Hardness : <2200HV0.5

Indicated Parosity : <0.2%

Volume Density : <3.00g/cm³

Compressive Strength : <2000Mpa

Fractural Strength : <350Mpa

5. Pump Components

6. Semiconductor

7. Metallurgical Engineering

8. Fixed and Moving Turbine Components

SIC Silicon Carbide Ceramic Seal Ring tungsten carbide mechanical seal

Tungsten carbide Mechanical Seal Ring is widely used as seal faces with resistant-wearing,

high fracture strength, high thermal conductivity, small heat expansion co-efficient. It is the

best material to resist heat and fracture in all hard face materials.

Tungsten Carbide Mechanical Seal Ring are used as Mechanical Seal faces in pumps,

Compressors and Agitators. These are used in Mechanical Seal Ring, Oil Refineries,

Petrochemical plants, Fertilizer Plants, and Drugs/Pharmaceutical Industries.

Mechanical seal rings are developed to withstand high temperature, high pressure & highly

corrosive chemical attack. we manufactures Rings in various shapes like Plain Ring, DA type,

T-shape, L-shape and in shapes as per customers requirement. Tungsten Carbide Rings are

generally made with Cobalt as binder material

Main : Ywn8/ywn6/yg8/yg6 Ni-binder Tungsten Carbide

Hardness : 88.5

Feature Strength : Tungsten Carbide Rings 1490

Processing Method : Cnc Machining Polising

5. Pump Components

6. Semiconductor

7. Metallurgical Engineering

8. Fixed and Moving Turbine Components

12/16/22 silicon carbide GLF-C pump mechanical seal

- Reaction Bonded Silicon Carbide (RB SiC) - a very economical material which gives

- excellent wear characteristics, as well as good chemical resistance.

- Sintered Silicon Carbide (SSiC) - the absence of free silicon makes it most resistant

- to chemically-aggressive fluids, and ideal for high temperature applications.

- Graphite-Loaded Silicon Carbide - this is a composite of silicon carbide and free

- graphite. Graphite is added to RB SiC (RB SiC + C) or SSiC (SSiC + C), to improve

- tribological behavior by enhanced lubricity.

(1) high hardness and wear resistance

(2) good corrosion resistance

(3) excellent mechanical strength

(4) good anti-oxidation

(5) good thermal shock resistance

(6) Low thermal expansion coefficient

(7) High thermal conductivity

Silicn Carbide Seal Face With Groove

application

it is usually be used in pumps , mechanical seal

Reaction Bonded Silicon Carbide (RB SiC) - a very economical material which

gives excellent wear characteristics, as well as good chemical resistance.

Sintered Silicon Carbide (SSiC) - the absence of free silicon makes it most

resistant to chemically-aggressive fluids, and ideal for high temperature applications.

Graphite-Loaded Silicon Carbide - this is a composite of silicon carbide and

free graphite. Graphite is added to RB SiC (RB SiC + C) or SSiC (SSiC + C),

to improve tribological behavior by enhanced lubricity.

Our product including :

1: mechanical seals for water pump: equivalent with John Crane, Aesseal, Flygt,GLF, and US Seal, etc.

mechanical seals model : MG1/MG12/MG13/560A/560D/155/TYPE2100/TYPE8-1/TYPE9/M7N/H7N/M3N/

58U/58B/1527/GLF/912/FBD/301/F water seal/PTFE SEAL WB2 & WB3 etc.

2: mechanical seals spare parts: made to order Silicon Carbide seal rings, sintered silicon carbide

seal rings, graphite carbon seal rings ,tungsten carbide seal rings, ceramic rings, rubber O rings,

springs, CNC machining service.

SSIC sintered silicon carbide seal ring carbide mechanical sealing rings

Our product including :

1 : mechanical seals for water pump:

mechanical seals model:

MG1/MG12/MG13/560A/560D/155/TYPE2100/TYPE8-1/TYPE9/M7N/H7N/M3N/

58U/58B/1527/GLF/912/FBD/301/F water seal/PTFE SEAL WB2 & WB3 etc.

2 : mechanical seals spare parts: made to order Silicon Carbide seal rings,

sintered silicon carbide seal rings, graphite carbon seal rings ,tungsten carbide

seal rings, ceramic rings, rubber O rings, springs, CNC machining service.

application

it is usually be used in pumps , mechanical seal

Reaction Bonded Silicon Carbide (RB SiC) - a very economical material which gives excellent wear

characteristics, as well as good chemical resistance.

Sintered Silicon Carbide (SSiC) - the absence of free silicon makes it most resistant to chemically-aggressive

fluids, and ideal for high temperature applications.

Graphite-Loaded Silicon Carbide - this is a composite of silicon carbide and free graphite. Graphite is added to

RB SiC (RB SiC + C) or SSiC (SSiC + C), to improve tribological behavior by enhanced lubricity.

custom silicon carbide mechanical seal water pump silicon carbide seal

Our product including :

1: mechanical seals for water pump: equivalent with John Crane, Aesseal, Flygt,GLF, and US Seal, etc

2: mechanical seals spare parts: made to order Silicon Carbide, sintered silicon carbide seal rings,

graphite carbon seal rings ,tungsten carbide seal rings, O rings, springs, CNC machining service.

The basic reaction bonded silicon carbide products contain a certain amount of free carbon

apart from the feature of resistance to wearing and high temperature. Compared with carbon

impregnated reaction bonded silicon carbide products, they can self-lubricate to a certain

extent, Widely used in the fields of heavy loading, poor ability to continuous lubrication ,

high requirement in corrosion resistant. Including the industries of automobile and Oil refining.

ndicated Parosity : <0.2%

Volume Density : <3.03 g/cm³

Hardness :<2200Hv0.5

Compressive Strength: <2000Mpa

Flexural Strength : <350Mpa

Free-Si value :<12%

Purity(SIC) : <98%

Elastic Modulus :350Gpa

Thermal Conductivity : 50-100 W/m. K

Coefficient Of Heat Expansion : 4.0 10 -61/<

Using Temperature : 1000<

Sintered Silicon Carbide Seal Ring Ssic Mechanical Seal Ring

application

it is usually be used in pumps , mechanical seal

Reaction Bonded Silicon Carbide (RB SiC) - a very economical material which gives

excellent wear characteristics, as well as good chemical resistance.

Sintered Silicon Carbide (SSiC) - the absence of free silicon makes it most resistant

to chemically-aggressive fluids, and ideal for high temperature applications.

Graphite-Loaded Silicon Carbide - this is a composite of silicon carbide and free

graphite. Graphite is added to RB SiC (RB SiC + C) or SSiC (SSiC + C), to improve

tribological behavior by enhanced lubricity

Hardness : <2200HV0.5

Indicated Parosity : <0.2%

Volume Density : <3.00g/cm³

Compressive Strength : <2000Mpa

Fractural Strength : <350Mpa

Coefficient Of Heat Expansion : <4 10 -6 1/<

Content of SIC : <98%

Content of Free Silicon : <12%

Elastic Modulus : <350Gpa

Using Temperature : <1000 <

Pressuring Sintered Silicon Carbide Pump Shaft Seal Ssic Seal Ring

Our product including:

1 : mechanical seals for water pump: equivalent with John Crane, Aesseal, Flygt,GLF, and US Seal, etc.

mechanical seals

MG1/MG12/MG13/560A/560D/155/TYPE2100/TYPE8-1/TYPE9/M7N/H7N/M3N/

58U/58B/1527/GLF/912/FBD/301/F water seal/PTFE SEAL WB2 & WB3 etc.

2: mechanical seals spare parts: made to order Silicon Carbide seal rings, sintered silicon carbide seal

rings, graphite carbon seal rings ,tungsten carbide seal rings, ceramic rings, rubber O rings, springs,

CNC machining service.

application

it is usually be used in pumps , mechanical seal

Reaction Bonded Silicon Carbide (RB SiC) - a very economical material which gives

excellent wear characteristics, as well as good chemical resistance.

Sintered Silicon Carbide (SSiC) - the absence of free silicon makes it most resistant to

chemically-aggressive fluids, and ideal for high temperature applications.

Graphite-Loaded Silicon Carbide - this is a composite of silicon carbide and free

graphite. Graphite is added to RB SiC (RB SiC + C) or SSiC (SSiC + C), to improve

tribological behavior by enhanced lubricity

sinterd silicon carbide rings sic silicon carbide ceramic mechanical seal ring

Sinter at atmosphere (normal) pressure, pressureless sintered silicon carbide.It has

outstanding high heat conductivity and thermal shock stability, also with the advantages

of better wear resistance, high temperature resistance,chemical corrosion resistance, high

PV value.so it can be especially used in critical requirements industry,such as food,

pharmaceutical and nuclear area.

Besides, SSiC is much more suitable for strong Acid&Alkali environment.

Hardness : <2600HV0.5

Indicated Parosity : <0.2%

Volume Density : <3.1-3.15g/cm³

Compressive Strength : <2200Mpa

Fractural Strength : <400Mpa

Coefficient Of Heat Expansion : 4 10 -6 1/<

Content of SIC : <99%

Elastic Modulus : <400Gpa

Thermal Conductivity : 90-110 W/m.K

Using Temperature : <1600<

Silicon Carbide G60 Stationary Seat Silicon Carbide Sic Seal Ring

Reaction bonded sintered silicon carbide;It is widely used as mechanical sealing in petroleum, chemical,automobile,valve and pump industry field

Hardness : <2200HV0.5

Indicated Parosity : <0.2%

Volume Density : <3.00g/cm³

Compressive Strength : <2000Mpa

Fractural Strength : <350Mpa

Coefficient Of Heat Expansion : 4 10 -6 1/

Content of SIC : <98%

Content of Free Silicon : <12%

Elastic Modulus : <350Gpa

Using Temperature : <1000

(1) high hardness and wear resistance

(2) good corrosion resistance

(3) excellent mechanical strength

(4) good anti-oxidation

(5) good thermal shock resistance

(6) Low thermal expansion coefficient

(7) High thermal conductivity

Reaction Bonded Silicon Carbide Rings

The basic reaction bonded silicon carbide products contain a certain amount

of free carbon apart from the feature of resistance to wearing and high

temperature. Compared with carbon impregnated reaction bonded silicon

carbide products, they can self-lubricate to a certain extent, Widely used

in the fields of heavy loading, poor ability to continuous lubrication ,

high requirement in corrosion resistant. Including the industries of

automobile and Oil refining

Indicated Parosity : <0.2%

Volume Density : <3.03 g/cm³

Hardness : <2200Hv0.5

Compressive Strength : <2000Mpa

Flexural Strength : <350Mp

Free-Si value : <12%

Purity(SIC): <98%

Elastic Modulus : 350Gpa

Thermal Conductivity : 50-100 W/m. K

Coefficient Of Heat Expansion : 4.0 10 -61/℃

Using Temperature : 1000

Carbon Seal Rings

- Self lubricating

- Resistance to corrosion

- Low thermal expansion

- Dry running properties

- Good thermal conductivity

- low coefficient of friction

- Excellent dimensional stability

- High fatigue resistance.

Pure carbon graphite is used for seals it will usually be impregnated with other

materials that are provided to variously improve the sealing ,by reducing porosity ,

improve the wear performance or increase strength. It is widely used, being one of

the face pair on the vast majority of mechanical seals, but also found as the most

popular material for segmented circumferential seals and for piston rings in dry or

marginally lubricated conditions.

Seal carbons are then impregnated to improve the properties. It is very common to impregnate the seals with synthetic resin

to convert the porous structure into a low permeable material. Higher duty materials can be impregnated with metal which can

provide an increase in the hardness and strength together with improved conductivity. A popular metal impregnated for seal

carbons is antimony. It is important for the metal to also have good bearing properties. The temperature limit of the finished

carbon component is usually dictated by the manufacturing process and impregnants that may be used. This will be for

instance the limit of the resin bonded or impregnated materials and the 'wiping' temperature of a bearing metal.

For non-impregnated grades the short-term limit of carbon graphite material is up to 350 Degrees C. and up to 500 Degree C.

for graphitized material.

Seal Ring Type G9

- Self lubricating

- Resistance to corrosion

- Low thermal expansion

- Dry running properties

- Good thermal conductivity

- low coefficient of friction

- Excellent dimensional stability

- High fatigue resistance.

Key Properties :

High wear resistance, self-lubricating, corrosion resistance, low thermal expansion,

good thermal conductivity, low coefficient of friction, excellent dimensional stability, high fatigue resistance

Primary Applications : Mechanical seals (face pairs), segmented circumferential seals, piston rings in dry or marginally lubricated conditions

Advantages of Pure Comfortable material with good dry running properties, wide temperature range, extensive chemical resistance, ability to

Carbon Graphite :re-establish carbon transfer film

Impregnation Purpose : Reduces porosity, improves wear performance, increases strength

Common Impregnants : Synthetic resin (converts porous structure into low permeable material), metal (e.g., antimony; increases hardness, strength,

conductivity; good bearing properties

Temperature Limits : Non-impregnated: up to 350°C, Graphitized: up to 500°C

Material Selection Criteria : Temperature resistance, chemical compatibility, recovery from transient upsets

Seal Ring Type G13

- Self lubricating

- Resistance to corrosion

- Low thermal expansion

- Dry running properties

- Good thermal conductivity

- low coefficient of friction

- Excellent dimensional stability

- High fatigue resistance.

Primary Applications :Mechanical seals, segmented circumferential seals, piston rings

Key Advantages : Good dry running properties, wide temperature range, extensive chemical resistance

Improvement Methods : Impregnation with synthetic resin, metals (e.g., antimony)

Benefits of Resin Impregnation :Converts porous structure into a low permeable material

Benefits of Metal Impregnation : Increases hardness, strength, and conductivity; provides good bearing properties

Temperature Limits :Non-impregnated: up to 350°C; Graphitized: up to 500°C

Chemical Compatibility : Excellent resistance to a wide range of chemicals

Recovery from Upset : Ability to re-establish a carbon transfer film

Multi Spring Unbalanced

Our products are designed to meet the stringent demands of various industrial applications, particularly where durability and reliability are crucial. Whether used in mechanical seals, segmented circumferential seals, or piston rings in dry or marginally lubricated conditions, our seal rings provide exceptional performance.

- Self lubricating

- Resistance to corrosion

- Low thermal expansion

- Dry running properties

- Good thermal conductivity

- low coefficient of friction

- Excellent dimensional stability

- High fatigue resistance.

M2N Seals

Carbon Seal Rings

Seal Ring is a part of Seal. It is combinational part in,Rotary Stationary It is called as Rotary Ring and Stationary Ring. As a mechanical seal manufacturer we have much stock of seal rings. The different materials used in rings are Carbon seal rings, Silicon carbide seal rings, Ceramic seal rings, Tungsten carbide seal rings, satellite seal rings etc.

- Self lubricating

- Resistance to corrosion

- Low thermal expansion

- Dry running properties

- Good thermal conductivity

- low coefficient of friction

- Excellent dimensional stability

- High fatigue resistance.

Carbon and graphite materials exhibit

Type 1

- Self lubricating

- Resistance to corrosion

- Excellent dimensional stability

- Low thermal expansion

- Dry running properties

- High fatigue resistance.

- Good thermal conductivity

- low coefficient of friction

Mechanical Seals and Bearings :Ideal for applications where traditional lubricants fail, such as in corrosive

environments or high-temperature conditions.

Electrical Applications : Used in electric motor brushes and contacts due to their excellent conductivity and thermal stability.

Chemical Processing : Resistant to chemical reactions, making them suitable for seals and components in chemical plants.

Aerospace and Automotive Industries :Utilized in components that require high wear resistance and lightweight materials.

Heat Management : Used in heat exchangers and thermal insulation due to their superior thermal conductivity.

Carbon and graphite materials exhibit

Type 4

- Self lubricating

- Resistance to corrosion

- Excellent dimensional stability

- Low thermal expansion

- Dry running properties

- High fatigue resistance.

- Good thermal conductivity

- low coefficient of friction

Mechanical Seals and Bearings :Ideal for applications where traditional lubricants fail, such as in corrosive

environments or high-temperature conditions.

Electrical Applications : Used in electric motor brushes and contacts due to their excellent conductivity and thermal stability.

Chemical Processing : Resistant to chemical reactions, making them suitable for seals and components in chemical plants.

Aerospace and Automotive Industries :Utilized in components that require high wear resistance and lightweight materials.

Heat Management : Used in heat exchangers and thermal insulation due to their superior thermal conductivity.

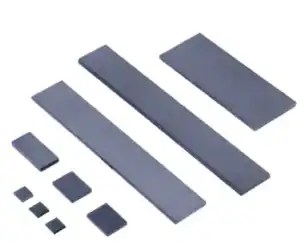

Graphite Blades

Our Carbon & Graphite blades have low specific density & self-lubricating

properties. They will work perfectly in hot or cold liquids. These are ideally

suited for rotary pumps handling water, petrol, fuel oils and other liquids.

Application :

Spray paint equipment

Packing machinery

Food processing equipment

Fuel tanker meters

Drink vending machines

Wet running vane pumps & meters

Automotive diesel fuel pump

Specifications

Size: Any size as per customers requirement

Type: Carbon Blades

Material: Carbon, Graphite

Shape:Rectangular

Thickness: Any size

Graphite Blades are self-lubricating and therefore ideal for pumps, handling liquids whose lubricating properties are poor, such as petrol, diesel etc. They can also operate in unlubricated compressors to deliver air or gas uncontaminated by lubricating oil or grease.

Carbon & Graphite Bushings

Our carbon and graphite bushings are highly efficient as bearings, especially in applications where traditional oil and grease lubricants are unsuitable. These bushings excel in environments involving corrosive liquids and gases, where contamination by conventional lubricants must be avoided.Our bushings are versatile and can be machined into parts of the required sizes, offering flexibility and customization. We pride ourselves on being among the most renowned carbon bushings manufacturers and graphite bushings suppliers in India, known for our high-quality products and reliable service.

Specifications

Type:Graphite Bushing

Material: Graphite & Carbon

Shape: Round

Size: Any size as per customers requirement

Thickness / Length: As per customers requirement upto 300mm

Application: All types of Pumps, Shafts, Mechanical Seals etc

Color:

Black, Grey

Carbon & Graphite Sealing Rings

We bring forth a premium range of mechanical carbon & graphite

sealing rings in the marketplace. We manufacture them in various

designs, shapes and sizes as per drgs or samples. Our Carbon graphite

sealing rings have close dimensional tolerance and is apt for usage

as a part of mechanical seals in general utility pumps, water pumps

and chemical pumps. The carbon sealing rings, we supply, are used

as the wear face of various mechanical seals for the sealing of fluids

in all types of industries. Carbon & graphite seal faces are compatible

with a wide range of other counter faces also. So, these qualities of our

products have made us one of the most reliable graphite sealing rings

manufacturers and suppliers in India.

Our carbon seal rings are specially designed for mechanical seal that are generally used in

railways for their diesel engines. The oil seal forms a vital component of railway brake system.

Manufactured from specially formulated carbon-graphite material with superior physical

properties, these mechanical carbon seal rings are machined to close dimensional tolerance

and lapped to two light bands. Today, we are considered as one of the venerable carbon sealing

rings manufacturers and exporters from India.

Carbon Wiper Blades

We manufacture Carbon wiper Blades which are used for specific application.

Our Carbon & Graphite Wiper blades have high density & they are self-lubricating.

They are used in refineries and oil industries.

Carbon Wiper have long life and high durability. They work very well with most

liquids. These Graphite wipers Can be manufactured in any sizes and different

grades as per customers requirement.

Specifications

Size : Any size as per customers requirement

Type :Carbon Wiper Blades

Material :Carbon Graphite

Shape :Rectangular

Thickness :Any size